Within a typical box die there will be cutting rule and crease. The obvious purpose of cutting rule is to cut out the box, and the crease is there to make an indented line used for folding the box into its desired shape. The importance of making sure the crease of a box is perfect is that, once creased, it is impossible to fix. Creases are the bones of the box. In this article we will discuss some of the aspects of crease and how we make sure your crease is correct.

Unlike rule, crease is measured based on the thickness of the material. The crease must always be somewhat lower than the height of the cutting rule so that the material is not crushed completely or fails to cut. Because of this, Fine Formes will always make sure you are using the right crease for the job. The formula for deciding height of crease is that it must be the thickness of the material plus 0.15mm shorter than the height of the rule. The extra 0.15 mm accounts for the tape used to secure matrix or counters.

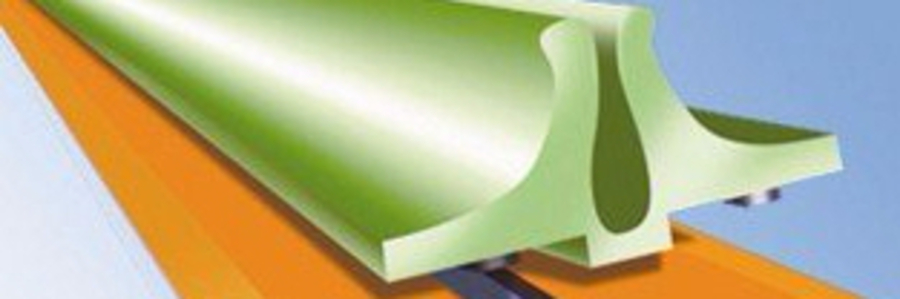

Matrix and counters have the same purpose; to help guide the crease and make it effective in creasing. Matrix is a strip of specifically shaped material that will make crease effective however it has some limitations. Because matrix is applied by the die cutter, Fine Formes does not supply or apply it. Instead we make counters which, at least from the die cutters perspective, are the easier method. The advantage of counters is that crease can bend. Matrix cannot accommodate crease that is not straight however the complexity of counters allows for any shape or distance between creases. This means the more complicated boxes need counters. Fine Formes can make counters and we would be pleased to answer any questions about this exciting new product.

Because crease is so important to the box, we at Fine Formes will always make sure the crease is on the line, every time. This guarantee means that the crease will always be square so that die itself has an accuracy of 0.1 of a millimetre according to the dieline supplied.

One final note on crease is that rubber is not required. This is because the crease does not need to be ejected and that the rubber would get in the way of the counter or matrix. Because of this, Fine Formes will always make sure there is no rubber close enough to the crease to be a problem when die cutting.

With this information on the ways crease is chosen and the supporting tools available you should be able to make better diecutting decisions. If you have any questions about what was discussed, or any other die or die making related questions, feel free to contact us.