In die making, cutting rule is the name of the metal knife used in the die to cut material. Because of its obvious importance in the die cutting procedure, choosing the right rule is imperative for success. In this article we will discuss the aspects of cutting rule and how their differences can help you get the perfect die for your situation.

To describe rule, we have six aspects that you can choose from, all of which can be combined in any manner;

Height

Bevel

Angle

Sharpness

Thickness

Hardness

Height

Rule height must be correct for a die to cut properly. This aspect is always made sure to be correct by all die makers and is confirmed with each die ordered. Generally the two most common heights of rule are 23.3 mm and 23.8 mm, colloquially named ‘low rule’ and ‘high rule’ respectively. Fine Formes will help make sure the correct height is being used for your machine.

Bevel

The bevel of rule refers to the shape of the cutting edge. This varies depending on the requirement of the material being cut. The standard is centre bevel for cutting single layer paper materials. If the material has multiple layers or needs to have particularly clean cuts, side bevel may be used as it will cut straight on one side and push into the waste on the other side. Additionally, both side and centre bevel can be ‘double long’ or long centre bevel/long side bevel. Double long bevel is suitable for thick material to make sure the material ejects correctly after cutting.

Angle

Fine Formes employs two types of angles in cutting rule. The first is 52 degree and is the standard due to its longevity. 52 degree cutting rule will outlast thinner angles but is still able to cut effectively. For situations where dust is a problem with the material being cut, 42 degree rule may be recommended as it is known to be dust reducing. This is because it reduces the amount of pressure required to cut the material, therefore lessening the effect of explosive penetration that all cutting rules use.

Sharpness

When cutting paper or similar materials, shaved edge rule is best. It is most common among cutting rules in terms of sharpness due to its very consistent height. The consistency has been achieved by the way it is made; where the rule is ‘shaved’ all along the top. With materials that need the cleanest possible cut at the expense of longevity of the die, ground edge is key. Ground edge has been ground between two stones so that all of the steel fibres are pointed up, making the edge extremely sharp. So sharp, in fact, that the rule is considered the most dangerous tool in die making and extreme caution is recommended when dealing with it. This rule is not used on normal die cutting because it is slightly less consistent in height and is more susceptible to becoming blunt quickly.

Thickness

The final aspect of cutting rule that you as the customer can help choose is the thickness. Thickness in printing is measured in points, where a point is equal to 0.35278 mm or rounded to 0.35 mm. Generally 2 point rule is used in standard dies however in corrugated packaging 3 point is used. There are also available higher points in thickness however this is specialist rule and will only be recommended by us in very rare occasions, usually for press knives rather than dies.

Hardness

Hardness of rule has been chosen by us at Fine Formes with extensive research into suppliers.

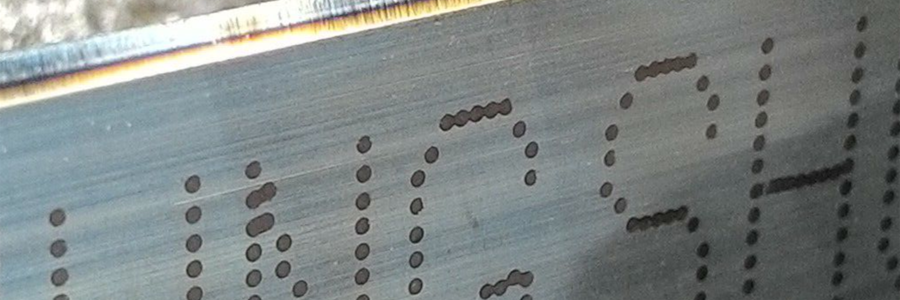

Hung Shuh is a world class supplier of forme making cutting and creasing rule.

The hardness is one of these qualities that enable us to create even the most complicated dies. Hung Shuh manufactures a cutting rule with a soft body and hardened edge, making the cutting rule last a lot longer but also allowing us to bend the rule into shape without causing cracks or splitting the steel.

Japan has been home to the world’s best steel for centuries and Hung Shuh has continued this tradition with its cutting rule. For more information on our cutting rule supplier visit their website or contact us. With this information on the way cutting rule is defined hopefully you will be able to make better packaging and die cutting decisions. For any clarification, enquiries or quotes, feel free to contact us and we will be happy to help.