In this article you will learn about the purpose of rubber, the different types available for use along with their specific advantages, and the methods in applying rubber to a die in the most effective format possible.

Rubber is the material that makes automated die cutting possible. The energy held in the rubber from compression acts as an opposing force to the diecutting press, causing ejection when the diecutting is complete. Rubber has three purposes of equal importance:

To hold the material being cut parallel to the cutting plate and rule edge.

To minimise distortion of the material when being cut.

To eject the material back to its original position after being cut.

There are multiple types of rubber that Fine Formes uses depending on the circumstances of the die. Typically a die is titled ‘low rule’ or ‘high rule’ where the cutting rule is 23.3 mm high or 23.8 mm high respectably. Confusingly, the 23.3 mm rule is traditionally called the ‘type high’ rule due to its history in the printing industry. We use a different accompanying height of rubber for a low or high rule die. This is calculated so that the rubber is always 1.2 mm higher than the rule when uncompressed.

Having the correct height of rubber is important for all three purposes. If the rubber is too low then ejection is impaired and if it is too high then the material has more room to move and distort whilst being cut.

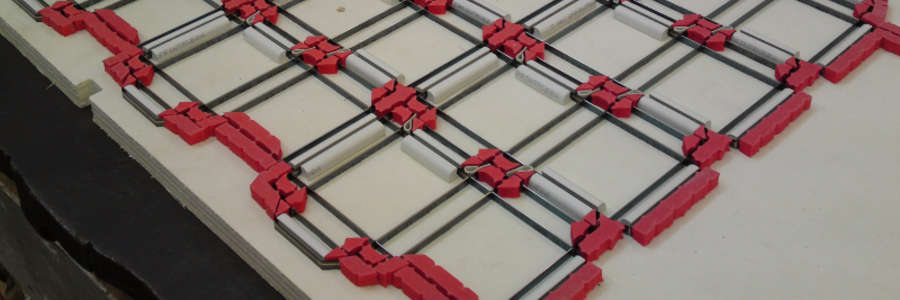

The teeth on our rubber is cut for a very important reason. If rubber is glued so that it is pressed up against the rule, when it is compressed, it will have nowhere to go but out, potentially blowing the knife out and ruining the die.

To make sure the material being cut is firmly held in place, we use a hard C-Channel rubber that pinches the material when compressed. When arranged correctly, the C-Channel rubber pulls the material tight so that it cannot move during diecutting.

In very tight areas with a lot of cutting rule, slot rubber may be required. This is made from the same rubber as C-Channel and is very hard, causing the material to eject very well. Sharp corners of boxes will usually need slot rubber otherwise the rule may ‘grab’ the material and stop ejection.

The rubber Fine Formes uses has been selected for its quality and has been in use for years without problems. With this information on the rubber we offer hopefully you will be able to make better packaging decisions related to ejection and ejection materials.